The Considerations That Go Into A More Productive Manufacturing Business

With manufacturing, productivity is what is going to make-or-break the business. If you could be producing 5% more in a day than you’re producing now, that’s a huge step you’re missing. So how do you go about making sure there are no gaps in your plans for production? As we’ll show you now, it’s about looking at all the different parts that play a role on the floor.

The Products

First, you need to look at the actual products that you’re manufacturing. If you’re the designer of those products, then have you considered a redesign? Reiterating on a product might seem risky, but it could make it all the easier to produce, meaning you get more done in less time. Especially if you’re able to outsource a part of that design. For example, if you’re able to get significant parts done with plastic injection moulding, that means a lot less has to be done on the floor.

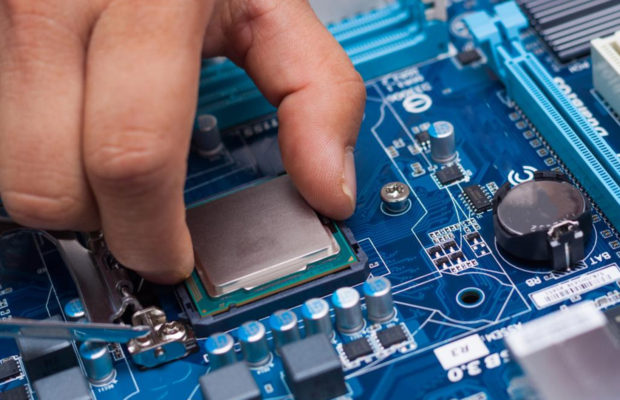

Taking Care Of Your Machinery

If you haven’t, already, then you need to look at the smart ideas behind lean manufacturing. There you will find that there’s one principle that keeps getting repeated time and time again. It’s about standardizing excellence in your machinery. Being able to identify the most important pieces and remove redundancies. Not only that, but making sure they’re in their best condition to decrease the odds of loss and work interruption. Maintenance, upgrades and inspections have to be a lot more common. If any manufacturing business intends on being a lot more productive, the machines are a priority.

Quantify All You Can

It’s not just about the changes that you make, either. It’s about how you use modern business tools to quantify and measure it all. The more accurate and specific you can be in measuring your business, the more you know whether you’re on the right track or not. For example, take a closer look at the workflow and points where it slows down. Use KPIs to measure how effective the changes you make are. Use modern technology to automate processes like admin that stop you from doing the tasks that make you money. It’s about the tech you use outside the manufacturing floor, not just the machines on it.

Keeping Efficient People

Of course, it goes beyond the tech, as well. The people play just as big a role in your productivity. They play an even bigger role when they’re not there. Absent employees, those with specific skills you need, is one of the biggest reasons for serious work interruption. So you need to create a more efficient team by having more than one person to fill any skill gap. There are lots of methods of training, like cross-training, to help you do that. The more qualified your team as a whole, the fewer worries you have about missing one of them.

The products. The machines. The people. The organisational tools. They all have an important role to play and they can all be a lot better at doing. Make sure you take an in-depth look to make sure your setup is allowing you to be as productive as possible.

© 2024

© 2024

0 comments