How Does Laser Etching On Glass Work?

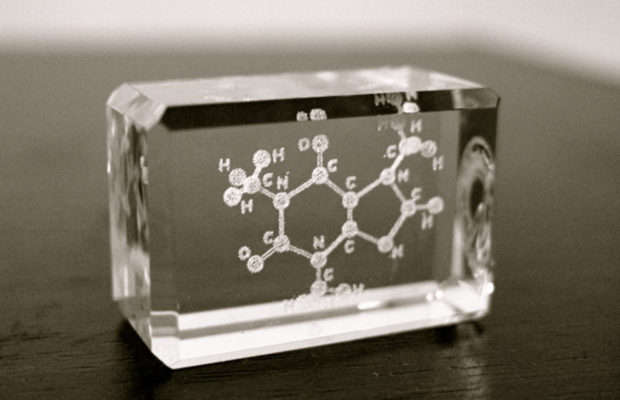

Laser etching on glass is used at specific frequencies, which affects how it interacts with different materials. Frequency relates to wavelengths of light that the laser produces, which determines what the laser will cut and what it will not cut. Glass etching is a delicate form of cutting into the glass to create an image, text, or pattern.

A low-power CO2 laser isn’t strong enough to mark metal, but it can etch glass. That’s because the low-power CO2 laser light works best on natural materials like wood, cork, glass (made from sand and natural resources), certain man-made plastics, and acrylic. Other types and methods of laser technology don’t work well with glass. Therefore low-power CO2 laser technology has the appropriate frequency to etch on glass.

Glass is considered a natural material because it comes from sand, an element of nature. When sand (a natural silicon-based element) is melted down, it turns into a gooey, thick fluid. That liquid can be poured into a mold, or blown by hand to create a variety of glass items. When molten glass cools down, it is transparent. Only if metals like zinc, gold, or cobalt are added to the molten glass does it take on any color. Knowing this is important to the next portion about how lasers etch on glass.

Something you probably don’t know is that CO2 lasers cannot engrave glass just like it cannot engrave metal, which is sometimes used in glass to create various colors and types of glass. This seems contradictory. So how does laser technology engrave on glass?

The process of melting sand to get glass happens at 2000 degrees and above. Once it’s molten, the fluid “glass” is manipulated one way or another. At this point, two new elements are introduced into the glass. Those elements are moisture and air. The air and moisture trapped inside the glass is what makes CO2 laser etching on glass possible.

When the laser beam makes contact with the glass, it heats up the silicon (sand) and whatever metal content may be inside the glass formula. While these elements are unaffected by the laser engraving process, the water and air trapped in the glass expand when heated up, resulting in microscopic fractures on the surface of the glass. The fractures, or chipping is what you actually see when you see laser engraved glass. If you look very closely, you will see tiny shards and fractures in the etching on glass.

Even with advanced technology and software applications, there is no perfect way to etch glass with a laser. Some people believe sandblasting or rotary methods are better for glass etching, but laser engraving is faster, more versatile, more forgiving, and less expensive than any other mechanical engraving or sandblasting process used for glass etching.

While laser engraving on glass isn’t as precise as sandblasting, it has other advantages that make it more desirable for engraving businesses. If you want to expand your laser engraving business to glass etching, be sure to learn the best methods and practices for creating beautiful glass etchings.

© 2024

© 2024

2 Comments